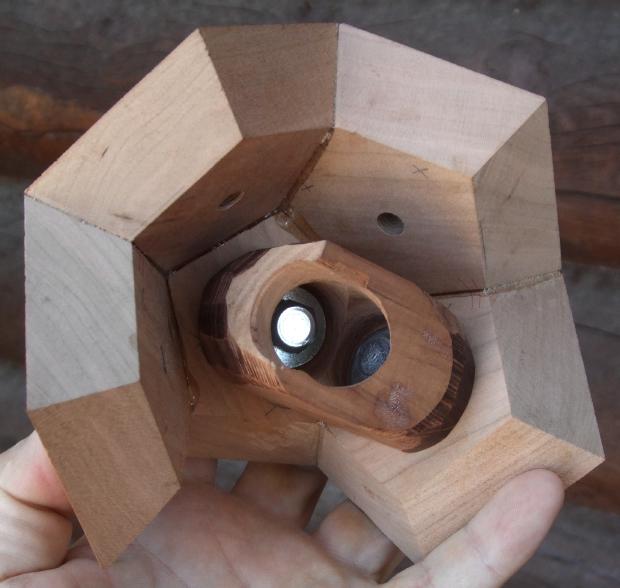

75% assembled.

The third-to-last piece added is the last one that can be held in alignment by screwing to a fixture. There's just enough room to get a wrench in to tighten the screws, and to remove them (and the fixture) after the glue has set.

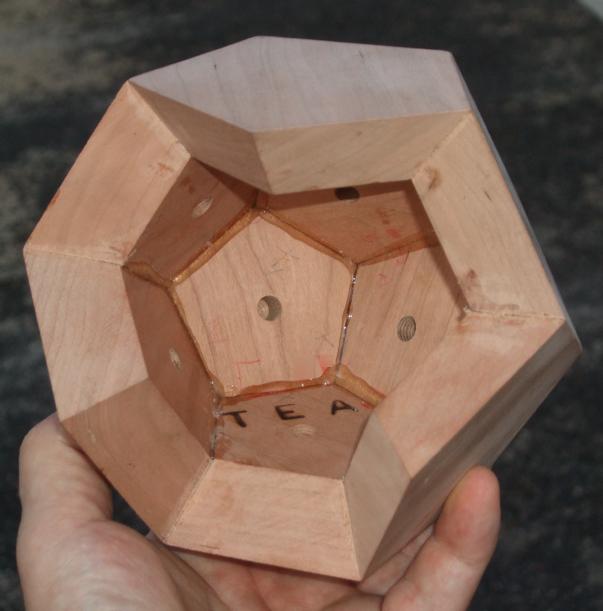

I've made a few different polyhedra before, and I've never had the last pieces go together without some extra attention. Even small errors in the alignment or shape of the previously assembled pieces can add up to something noticeable in the end. This, the final piece to be glued in, is not perfectly regular; it was cut to the shape of the last remaining space, whose bottom edge is about 2mm shorter than adjacent edges.

The pentagonal pieces are cut with a table saw. The beveled edges come from tilting the table and the 108° angles of the pentagons come from a sled made for the purpose. The sled has wood strips attached on its underside that fit in the grooves of the table; this arrangement constrains the sled to move in a straight line parallel to the blade.

The sled maintains control over the shape of the pentagons and makes it possible to cut small pieces of wood safely. The pentagon on the sled in this photo has had three edges cut and has two edges remaining to be cut.